What is Six Sigma, and how can Six Sigma training reduce costs? Six Sigma can refer to a metric, a management philosophy, a business strategy or a methodology. In many companies, it means striving for near perfection by continuously measuring and analyzing data, to reduce variations in quality, eliminate product defects and malfunctions, and reduce service failures. Its methods for improving quality and efficiency are as important as reducing costs, but our focus will be on the latter.

What is Six Sigma, and how can Six Sigma training reduce costs? Six Sigma can refer to a metric, a management philosophy, a business strategy or a methodology. In many companies, it means striving for near perfection by continuously measuring and analyzing data, to reduce variations in quality, eliminate product defects and malfunctions, and reduce service failures. Its methods for improving quality and efficiency are as important as reducing costs, but our focus will be on the latter.

Six Sigma Is Used In Many Industries

Six Sigma was developed in 1987 at Motorola. Soon after, Jack Welch, former CEO of General Electric, implemented Six Sigma throughout his company, with great results. In fact, the 1997 GE Annual Report states that Six Sigma added $300 million to GE’s bottom line. In its first five years of implementation, Six Sigma saved GE approximately $10 billion. Partly due to the notoriety of GE’s achievements, the value of Six Sigma training and certification became widely known, and spread quickly to private and public firms in industries such as manufacturing, finance, aerospace and automotive, as well as in government and military organizations. In finance alone, Six Sigma’s methods have been adopted as a proven route to error free processes and waste reduction. Thus, accountants as well as those preparing to become a CPA, have begun learning this methodology as part of their accounting academia and exam preparation as six sigma has proven to be beneficial for any business entity that entails a product or service.

Using Six Sigma to Reduce Costs

When business managers seek ways to cut costs, they frequently look at the largest cost centers, and implement only short-term solutions – often, with results that affect customer satisfaction. With Six Sigma, a company’s processes – not just cost centers – can be systematically measured and analyzed to produce real, sustainable results. From inventory control to labor, energy use to transportation, eliminating waste and improving efficiency in all areas of operations can reduce costs, with no negative effect on customer satisfaction.

Cost of Poor Quality (COPQ)

Defects cause an increase in costs. Six Sigma’s improvement methodologies can reduce the number of defects; therefore, it can reduce costs. Beyond defects, every company suffers losses due to cost of poor quality (COPQ). Some of the costs associated with poor quality include:

- Scrap

- Loss of customer loyalty

- Lost sales

- Higher risk

- Increased administrative costs

- Returns and allowances

- Lower employee morale

- Warranty repairs and replacement

- Service calls

Some experts say the average firm loses 5 – 30% of gross sales to COPQ. It’s impossible to know how many firms mistakenly operate under the assumption that they’re at the low end of the scale, but it’s fair to say countless others don’t even know where they stand with COPQ. One Fortune 500 firm recently calculated its COPQ figure at 8.6% of sales, and set a goal to reduce it to 5.4%. The result will be nearly $1 billion in cost savings. Implementing Six Sigma training can reduce any company’s COPQ, by teaching personnel how to create a repeatable, reproducible system of quality improvement.

Six Sigma and a Focus on the Customer

Improving the quality of customer service is another way Six Sigma certification can help companies reduce costs. By focusing on the customer’s needs and wants, those products and processes that do not serve the customer can be eliminated. In Six Sigma firms, employees with Six Sigma training use their skills to gather data, analyze it and create more effective processes – instead of working from assumptions. In addition, taking steps through Six Sigma to reduce defects and poor quality can result in greater customer satisfaction, improved brand loyalty and increased market share.

Case Study: U.S. Army Uses Six Sigma To Cut Costs

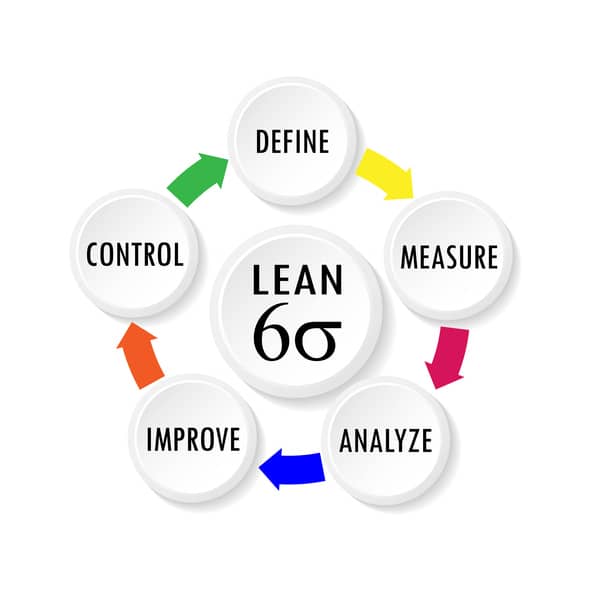

Since 2005, the U.S. Army has incorporated the principles of Lean Six Sigma to reduce costs, while improving the effectiveness of processes and meeting customer expectations. The logistics in moving forces, equipment and support supplies out of Iraq and into Afghanistan required the skills of Lean Six Sigma professionals, who were brought in to analyze the objectives and limitations, and recommend the most efficient and effective processes. By focusing on the needs of the soldiers (the “customers”) these experts improved flow to eliminate delivery failures and reduce costs. The results? In 2009, an astounding $3.8 billion in cost savings was reported, due in large part to Lean Six Sigma methodologies.

Effective Six Sigma Training

Six Sigma has created transformative results in organizations worldwide. But a company’s Six Sigma certifications are only as good as the quality of its Six Sigma training. When significant savings are on the line, choosing a Six Sigma training course is worth careful review which again reflects on the necessity of including these methods into accounting and CPA classes.

The first level of Six Sigma certification is Green Belt. Black Belt is the next level; these experts are sought-after leaders in many organizations, and often serve as coaches to Green Belts. And then comes Master Black Belt Six Sigma certification, which focuses on leadership and improvement design.

There are plenty of Six Sigma books, articles and weekend seminars available, but effective Six Sigma training takes time and effort. There is no substitute for an in-depth Six Sigma certification programs with outstanding instructors and a reputation for excellence. Green Belt training can last from two to eight weeks, while Black Belt courses often last 16 weeks. Six Sigma Master Black Belt courses are typically completed in 12 weeks.

So when your company decides to implement Six Sigma training and certification to reduce costs, choose a program that offers top-quality, thorough instruction. Six Sigma training is intense – but it’s a proven investment that can reduce defects, improve quality, cut costs and transform your entire organization.