Written by: Jesse Allred

Visual management, or visual control, can help create a solid foundation for 5S projects. The philosophy of 5S represents a way of thinking to better organize and manage workspace, specifically by eliminating the eight wastes as defined by the Lean Manufacturing system.

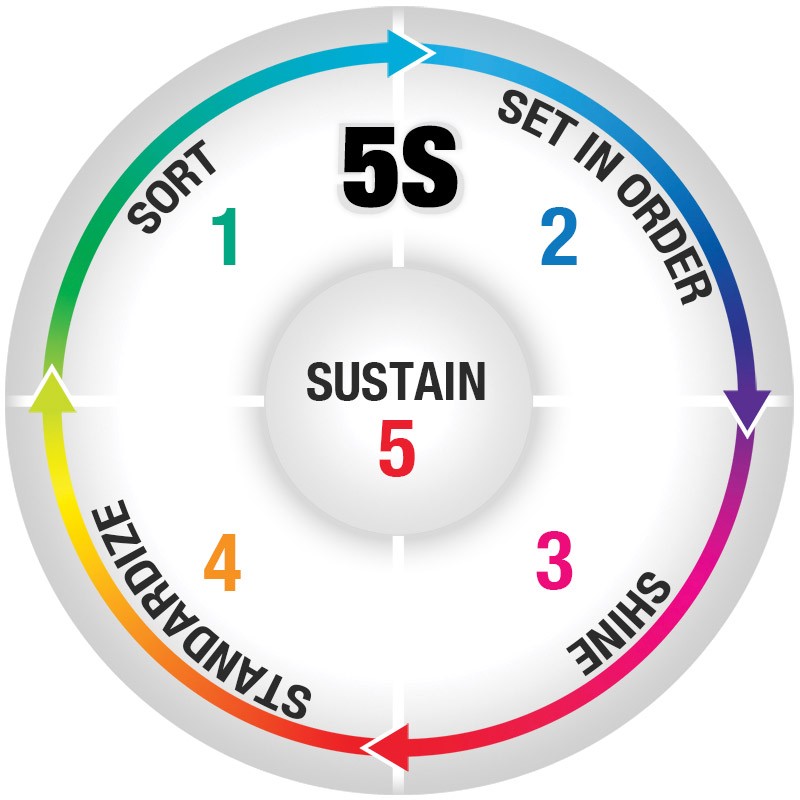

Managing a workspace includes communicating expectations, information, standards, or warnings through visuals like colors, words, pictures or symbols. Visual control can be essential for safety and Lean efforts in the workplace. 5S, a Lean methodology, uses a series of steps to help accomplish this:

- Sort

- Set in Order

- Shine

- Standardize

- Sustain

Applying 5S to a workspace can help guide individuals through organizing and cleaning nearly any spot in a facility, including workbenches, work cells, tool chests and offices, and its system can be implemented inside and outside of the workplace. 5S works to remove unnecessary materials from spaces, organize items in spaces, clean, perform maintenance and ensure they become regular habits for workers.

Best Practices for Visual Communication and 5S

Many of the steps in the 5S framework can effectively utilize visual management and help keep things in order and the process running smoothly. The following are some examples of tools and practices used to aid in the organizational efforts of 5S.

Labels: Labels are arguably the most useful tool for organizational strategy. Several areas and items in a space can be labeled. For example, you can place labels on tool drawers to identify contents or label shelves indicating where larger tools are to be stored. The floor can even be labeled to indicate where machinery, carts, trash cans and other equipment should be placed. Labels helps workers know where items are stored should they need to move or use them.

Shadow boards: Tools can become one of the most disorganized materials in a facility, however, shadow boards can help improve organization and ensure tools are stored properly. Essentially, a shadow board is a backing, usually a bright color, that is visible when a tool is removed from a pegboard or tool chest.

Floor markings: Floor tape is self-explanatory, but it can have a dramatic impact on visual workplaces. You can use floor tape to create defined spaces in an otherwise open facility floor or mark off work areas and create specific locations for pallets, raw materials, finished goods, shipping and other static locations.

Wall signs and banners: Signs, posters, and banners are other methods that may help sustain your 5S efforts. Large signs can be hung above storage areas to indicate where tools and equipment are stored. You can also use posters to indicate cleanup areas and remind workers of the importance of 5S.

Red tags: Sorting, the first step of 5S, is designed to help go through the items in the space and decide what to do with them. 5S red tags are a tool used during this process to identify objects that may need to be removed, recycled or relocated. The idea of using red tags is to place items you may be unsure about in a kind of “holding area” to give you time to evaluate their necessity. You can mark off a red tag holding area with red floor tape and post signs indicating the red tag area. After some time has passed, you can reevaluate the items by checking their red tag and decide whether they need to be relocated or removed from the facility entirely.

Color coding: Having color-coding standards in your workplace can help ensure a uniform style for your visual workplace. Color coding can apply to a variety of areas, including color coding shadow boards for tools, or following the color code for floor marking standards. Another tool that can be used is a color-coded work board. These are work boards that are updated on a regular basis provide instructions on everyone’s tasks in the workplace. Implementing a color-coded board can help employees keep track of their work tasks and 5S activities.

Reorganizing your facility may seem like a daunting task, but the methodology and framework of 5S can help guide you through the steps. Using principles of visual control may help strengthen your organizational efforts and better help you communicate standards to your workers. A combination of floor markings, labels and signs are an efficient and cost-effective way to ensure a clean and organized workspace is at the forefront of everyone’s mind.