Written by Contributing Columnist: David Larsen, PSP, PMP, LSSMBB

Operational leaders have many responsibilities within an organization. Responsibilities span from day-to-day business to people-leadership. But when does a leader take time to identify process improvements?

Walking the workplace, or Gemba walk, is an ideal opportunity to meet the needs of connecting with team members and identifying barriers to business processes. This article details some best practices to help you walk your workplace, engage your team, and improve the business.

Gemba Walk

Walking the workplace is an essential step for the operational leader and it is foundational of the Lean management philosophy. The initial purpose is to enable and allow leaders to observe the process, connect with team members, gain knowledge or insights regarding the work process, and consider opportunities for improvement.

Gemba is a Japanese term, defined as the actual place. Lean management describes Gemba as the place where value is created or where the actual work happens. Examples: for healthcare, it’s delivering care to a patient. For manufacturing, it’s the production floor and product flow. For human resources, it’s the employee experience. The walk takes you, the leader, to where the actual work occurs, so it’s observable and able to be evaluated.

There are three important elements to include when on a walk of the workplace: go and see, ask why, and respect for people.

- Go and see: the main purpose of the walk is for leaders on every level to regularly walk the work areas and be involved in finding wasteful activities.

- Ask why: the learning objective of the walk is to explore the process (value stream) and locate the problematic parts through active communication with team members.

- Respect for people: the walk provides the leader with the opportunity to collaborate with the team to identify and solve problems together.

The operational leader can personify principles attributed to Dr. Shigeo Shingo as the basis for building a sustainable culture of operational excellence. Principles that align with walking the workplace include respect for every individual, a focus on process and leading with humility.

Steps to Follow When Walking Your Workplace

Prior to taking a Gemba walk, remember to make a plan. The plan will depend on the goals and objectives of the walk – to be prepared, efficient and effective. Checklists give structure to your initiatives, and ensure the team is aligned. Additionally, a checklist can help you establish priorities, set goals, and evaluate that processes are following standard work.

Of course, a walk can be performed without a checklist, but the chance of forgetting to ask a question or missing a crucial step are higher without a list to guide you. In manufacturing, it’s good standard practice to document processes for future reference and training. This standardizes operations and ensures quality is not impacted.

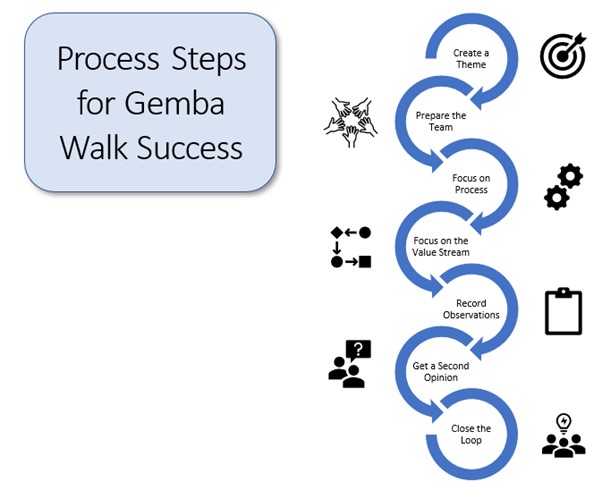

Next, let’s consider the process steps of the walk plan checklist. The following steps are recommended: create a theme, prepare a team, focus on process, focus on the value stream, record observations, get a second opinion, and close the loop.

Create a Theme: This helps to focus effort and effectiveness. Themes to explore include productivity, cost efficiency, safety, etc. With the theme selected, prepare a list of questions tailored to the theme to consistently ask team members. Questions to include on the checklist do not need to be complex or difficult to understand. The following are example questions to consider:

- Do you experience any problems with the established process?

- Is there an established process for this type of work?

- What are the inputs and outputs of the process?

- What are the obstacles to the process or waste producers?

- What would you do to recognize the root cause of a problem?

- Who would you speak with if there is a problem?

- How could the problem be fixed?

Prepare the Team: Communicate with the team that will be observed. Explain the purpose of the Gemba walk, and what to expect. Share your checklist ahead of time with the team. The goal is to gain buy-in from the team, change perception of the observation from evaluation to collaboration, and engage the team to raise questions to drive process improvement.

Focus on Process: The Gemba walk is not the time to evaluate the team’s performance. The purpose is to observe, understand and improve the process. The checklist provides guardrails to keep the focus on the process, not on people.

Focus on the Value Stream: Planning the walk ahead of time, mapping the process and building a checklist helps result in a focus on the value stream. The value stream can be defined as the process activities that occur to add value to your product and are desired by your customer. Non-value-added activities are those that are not important to your customer, and they are not willing to pay for them. Removing bottlenecks, waste, and non-value-added activities will improve the overall performance.

Record Observations: Record everything and determine actions later. Avoid making assumptions, conclusions, or recommendations during the walk. Data collections and recording information is important. Take notes or video record and document findings.

Get a Second Opinion: Consider performing an observation on the process by a colleague from another department; someone less familiar with the process can help provide a fresh perspective. Determine if the existing checklist will be used or if the colleague will write their own and compare checklists to identify gaps in thinking.

Close the Loop: Share the observations with the team, regardless of outcome. This fosters the collaboration and feedback between stakeholders and minimizes the feelings of being watched. Discuss the findings and opportunities with the team, allowing their voice to be heard prior to acting or implementing solutions. Plan and perform future walks to observe the implemented changes and if desired results are achieved and maintained.

Gemba walks are a foundational observation method for assessing business operations. When performed on a regular basis, they can offer significant advantages such as building stable relationships with those who perform the work and create value, identifying problems and taking actions for achieving continuous improvement efficiently, and clearly communicating goals and objectives leading to increased employee engagement.

Bio:

David is a certified Planning and Scheduling Professional, certified Project Management Professional (PMP ®), Lean Six Sigma Master Black Belt, author and podcast guest with more than 20 years of experience in human resources, healthcare, manufacturing, quality and process improvement. Success comes from challenging the current state and asking tough questions. He coaches and develops others while practicing servant leadership; striving to establish collaborative and trustful relationships with individuals at all levels. He has experience leading large and complex cross functional project teams, coaching team members, and facilitating for success. A principle that he believes to be fundamental is learning to take every challenge as either a gateway to success or an opportunity to learn.

Social Media: