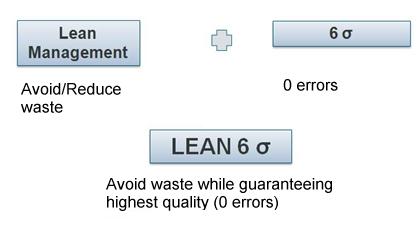

Lean Six Sigma combines Six Sigma strategies that focus on eliminating process variation and errors with Lean strategies that focus on reducing process waste by eliminating non-value adding actions. Both strive to create consistent workflow processes that result in better products and services, as well as an improved bottom line.

While there are differences between Six Sigma vs. Lean, the term Lean Six Sigma is used more often in the business world because elements of both Lean and Six Sigma are needed to make processes as efficient and effective as possible.

Lean Six Sigma certification, or at least a strong working knowledge of both methodologies, is critical to business success in a highly competitive, increasingly global marketplace. A good place to start is with the basics.

What’s the Goal of Lean Six Sigma?

Those who use Lean Six Sigma aspire to attain better business results, including more efficient use of time and materials, smoother work flows, more satisfied customers and an increased profit margin.

Lean Six Sigma takes the fundamental Six Sigma strategies for streamlining business processes and applies them alongside Lean strategies of product production. The result is a hybridized system for making all aspects of a business run more effectively.

Who Benefits From Lean Six Sigma?

While Lean Six Sigma has its roots in manufacturing, it’s effective in a wide variety of industries. Every business can benefit from putting the principles of Lean Six Sigma into practice, whether it’s in the front office or on the manufacturing floor. Some of the industries beyond manufacturing where Lean has become popular include the following.

Healthcare: Medical operations in all areas of healthcare, including hospitals and medical supply chains, turn to Lean Six Sigma to improve delivery of medical services.

Financial and legal services: Legal operations have started to use Lean Six Sigma to improve office functions and reduce paperwork.

Education: School administration and faculty know the value of teaching students about Lean Six Sigma, as well as applying it to their own operations.

Retail: Retail businesses, facing many challenges with the emergence of online shopping, have turned to Lean Six Sigma with a special focus on improving customer satisfaction.

Office-based businesses: Office environments are a good target for Lean Six Sigma techniques because they frequently have difficulties with managing supplies, duplicating processes and using all the talent available on staff.

Small businesses: By putting Lean Six Sigma methodology into practice, small businesses can beat the odds and stay in their industry for the long-haul, providing products and services created with a customer-first focus.

Differences Between Lean and Six Sigma

Lean Six Sigma combines aspects of the two methodologies. Both started in manufacturing but have since spread throughout the business world. The end goal of both is to support an organization in adopting a culture of continuous improvement that leads to better efficiency, profitability and customer satisfaction.

Six Sigma

Six Sigma strategies reduce process variance, eliminating errors that lead to defects in a product or service. The term “Six Sigma” refers to reaching a state where there are only 3.4 defects for every one million opportunities.

Most people know Six Sigma from two data-driven methods that businesses often employ.

- DMAIC: Define, measure, analyze, improve and control. Businesses use DMAIC to identify and correct errors in an existing operation.

- DMADV: Define, measure, analyze, design and verify. DMADV is used to create new processes, products or services.

Lean

Lean focuses on eliminating waste. Every aspect of an operation is considered in detail, with processes that add value separated from non-value adding processes that do not serve the end user (the customer).

The waste targeted by Lean typically falls into categories known collectively as the Eight Wastes of Lean.

- Defects: Process errors that lead to low-quality products and services

- Overproduction: Producing more products than current demand requires.

- Waiting: Idle time between two tasks within a process

- Non-utilized talent: Allowing employee skills to go to waste.

- Excess inventory: Wasting space to house excess inventory

- Transportation: Non-streamlined transportation leads to wasted time and money

- Unnecessary actions: This refers to employees or machines performing actions that don’t add benefit to the product or customers.

- Extra processing: Doing more than what is necessary (such as unnecessary paperwork duplication).

Responding to a changing marketplace while continually improving performance standards is vital for staying ahead of the competition. Lean Six Sigma strategies help business leaders improve company performance and increase product consistency. Organically evolving alongside Six Sigma, Lean strategies in manufacturing complement an already strong approach to business challenges.

For leaders looking to manage their organizations more effectively, Six Sigma and Lean Six Sigma training can prove to be a wise investment.