Written by Contributing Columnist: David Larsen, PSP, PMP, LSSMBB

It had been a long time since I’d last visited an amusement park. But my children were older and tall enough to enjoy the thrilling rides and attractions featured at these destination locations, so when my wife and I learned about a theme park near our home that was offering discounts on annual passes, we opted to become members.

As a continuous improvement leader, I find that I am in observation mode most of the time, watching and analyzing people and procedures while enjoying the quality time with my family. On this most recent visit to the theme park, I enjoyed several attractions and observed best practices, but also identified some opportunities for improvement.

Rollercoaster Visual Management

The first thing I observed was the rollercoaster experience. We attended the park on a busy day. The park offered a ‘Fast Pass’ option, which is a special ticket or purchase that allows park guests to bypass longer lines and enjoy attractions or rides faster than average. In my expert opinion, a Fast Pass is an industry best practice, both as a guest incentive and aid to load balance attractions.

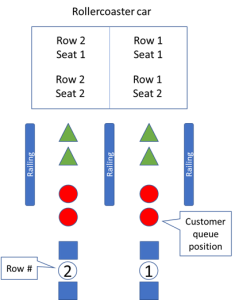

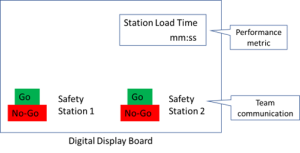

When we got in line for the first rollercoaster, I observed multiple Lean practices of visual management for the customer and park team member. Examples of visual management for the customer included signs indicating front row and back row train positioning and floor markings indicating row number and loading order. Examples of visual management for the team member included a digital station check board with load time metrics.

Images 1 and 2. Examples of visual management. Images by David Larsen.

However, when we visited another rollercoaster, one that had been a mainstay at the park for many years, I observed inconsistencies in the visual management. Notably, the lighting in the train loading area was dim, the signs that were supposed to draw attention to train position were missing, and there were no floor markings to indicate loading order. Overall, while both rollercoasters were thrilling, and park team members managed the visitors with efficiency, I saw clear opportunities for improvement.

Dining Reflections

Upon entering the park further, I noticed other opportunities related to food service. First, we found that many quick service food option kiosks were closed. We attempted to dine at a café and member lounge mid-afternoon, only to be informed that the café was closed, and would reopen in 45 minutes. Learning this, we attempted to dine at a member lounge, but once checked in, we were informed that only two servers were on staff at the time. After one hour of waiting, with our order still not taken, we decided to relocate to another restaurant, a grill, where we waited for approximately 1.5-hours for our meals.

Our experience at the grill was confusing – long entry waiting lines, unclear line locations to obtain specific menu items, a cashier unaware of the annual pass discount, and team members working hard to barely keep up with guest demand.

As I waited in line, I found myself reflecting on the day and asking questions:

- Is the park experiencing short-staffing?

- Does the park trend past attendance numbers to aid in staffing plans?

- Are customer food purchases analyzed to forecast production needs, schedules, and plan breaks?

- Do members of park leadership walk the park throughout the operational day to observe processes and check-in with team members?

- How is customer experience data collected, analyzed, and action-planned to improve the park?

- What mechanism does the team member have to improve their process, without reproach?

I also thought how I might problem solve what I was experiencing today related to food service and my overall experience at the park.

Applying Lean Principles to a Theme Park Experience

Lean thinking is focused on adding value, with value being defined by the customer. Lean methodology has its roots in manufacturing, but there are tons of applications and examples of how Lean has impacted operations in other industries. An amusement park can be categorized as a service or entertainment industry which includes hospitality. The customer interface for most aspects is physically being at the park. This proximity to the customer should be viewed as an advantage to any organization interested in understanding and meeting their customers’ expectations.

Given the opportunity to be collaborator at this amusement park, I would charter a project with park leadership to introduce Lean thinking. This would enable the park to increase profits through eliminating waste and improving the quality of key culinary and attraction processes while at the same time increasing customer and team member satisfaction. Objectives would need to be clearly defined to achieve project success, such as:

- Understanding the voice of the customer related to culinary services at the park

- Establishing data that captures current processes and required resources

- Identifying and prioritizing the value stream(s), and analyze to determine flow

- Proposing and validating possible improvements to a value stream that would generate maximum benefits

- Ensuring improvement sustainability through involving front-line team members and knowledge management.

Lean is not a set of tools, rather it is an operational philosophy. Lean considers waste prevention and focuses on customer value in a flexible and responsive way to sustain and improve the business of the organization. Lean thinking employs a variety of tools for visualization and standardization. By applying investigative techniques, process mapping, visual control concepts, and incentive plans, Lean allows positive change to occur. My thoughts drifted to deliverables that a project might yield:

- Current and future state process maps

- Process walk plans, interviews, observations, and analysis

- 5S assessment and plan

- Work-cell layout

- Staffing and resource plan

- Onboarding and training documentation

- Recommendations for future improvements

Lean enhances an effective response to the needs of customers by providing efficient and valuable services. Lean applied within an organization is a solution to track costs while optimizing processes identified with repetitive and wasteful steps, transforming into flexible and adaptive processes. When implementing Lean, it is essential to involve the front-line team members because they typically have the best understanding of the processes of the organization, and their involvement will help sustain the implemented changes.

The key learning from my experience is that when encountering a negative event, consider what steps you might take to influence and effect change. It’s easy to live in the moment and complain about it, but it requires energy and perseverance to seek solutions to the situation. By focusing on customer value and the elimination of waste across functional boundaries, it is possible to produce savings and increase profit without negatively affecting customer or team member experience. The questions, answers, deliverables, and training materials resulting from a project team can, when used consistently, empower leadership and team members to continuously improve processes throughout an organization and focus on value-added activities.

Bio:

David is a certified Planning and Scheduling Professional, certified Project Management Professional (PMP ®), Lean Six Sigma Master Black Belt, author and podcast guest with more than 20 years of experience in human resources, healthcare, manufacturing, quality and process improvement. Success comes from challenging the current state and asking tough questions. He coaches and develops others while practicing servant leadership; striving to establish collaborative and trustful relationships with individuals at all levels. He has experience leading large and complex cross functional project teams, coaching team members, and facilitating for success. A principle that he believes to be fundamental is learning to take every challenge as either a gateway to success or an opportunity to learn.

Social Media: