Written by Contributing Columnist: David Larsen, PSP, PMP, LSSBB

Continuous improvement leaders support a variety of processes, projects, and people. With so many variables interacting and affecting the velocity of a project, it can be difficult to understand how each of the elements come together to influence outcomes. A Product-Process matrix will help determine where to focus resources on data collection and observation, which in turn, can help create a value stream map with the least amount of time and effort.

What is a Product-Process Matrix?

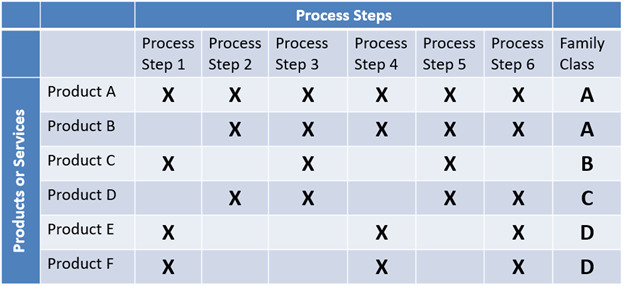

A Product-Process matrix (PPM) is a visual tool to identify and communicate the relationship between process steps and products or services. This can have applications as a precursor to a value stream, root cause analysis, bottleneck identification, and so on. The matrix, also called a Product Family matrix (PFM), was introduced by Robert H. Hayes and Steven C. Wheelwright in Harvard Business Review articles in 1979, entitled “Link Manufacturing Process and Product Life Cycles” and “The Dynamics of Process-Product Life Cycles.” In the articles, the two authors examined market manufacturing process issues and used the matrix to create strategic options for the company.

The PPM, also known as a relationship matrix, is an effective tool for scoping work, determining the applicability of data, and preparing the value stream mapping process. The matrix can also help leaders and teams identify the high-level interactions and dependencies of products/services/hand-offs to drive better decisions, solve problems, and improve processes.

With any project or continuous improvement initiative, the project leader has the opportunity to personify principles attributed to Dr. Shigeo Shingo as the basis for building a sustainable culture of operational excellence. Principles that align with the Product-Process matrix include creating value for the customer and improving flow and pull.

How to Build a Product-Process Matrix

Creating a Product-Process matrix is a “hands-on” activity that requires a team. Project leaders should adhere to the following steps to build a PPM.

First, identify the purpose or the problem to investigate. Then, assemble the team, and remember to include frontline workers as a part of the team. Having frontline workers as part of the team is an opportunity for them to be a part of solving the problem – leveraging their experiences with the process to identify and address operational issues.

Next, define the high-level process steps involved with the business unit or with the project. The process steps should be arranged by flow order with downstream processes last. Downstream steps are those process steps that are closer to the customer. List the process steps across the top of the matrix.

Afterward, discuss and list the products, services, or flow of information that passes from process step to step. There is an opportunity to capture the roles or individuals involved in creating the products or performing the service; this information may prove useful when evaluating process bottlenecks or improvement opportunities. List each product or service down the side of the matrix.

Finally, identify and mark which products or services associate with each process step. Classify your products or services into “families” based on the similarity of process flow. You may want to include other factors as a part of the matrix such as processing time per unit, volume, or yield.

A word of caution regarding low-volume offerings: Low-volume products have a disproportionate impact on complexity. Several low-volume offerings can be grouped into a single-family class, but do not group low-volume with higher-volume offerings. Have a goal to group the products/services into 3-10 family classes.

Product-Process matrices are useful to create prior to mapping the value stream to identify representative products, services, or information to include in the process. Through the use of the matrix, take the opportunity to incorporate the voice of the customer into the process flow and the products or services. A Product-Process matrix will help a team to visualize where to focus, leading to the creation of a value stream map.

Bio:

David is a certified Planning and Scheduling Professional, certified Project Management Professional (PMP ®), Lean Six Sigma Black Belt, author, and podcast guest with more than 20 years of experience in healthcare, manufacturing, quality, and process improvement. Success comes from challenging the current state and asking tough questions. He coaches and develops others while practicing servant leadership; striving to establish collaborative and trustful relationships with individuals at all levels. He has experience leading large and complex cross-functional project teams, coaching team members, and facilitating for success. A principle that he believes to be fundamental is learning to take every challenge as either a gateway to success or an opportunity to learn.

Social Media: